The OHB project was dministrated by Professor Joachim Oppelt from the Institute of Subsurface Energy Systems (ITE) and fundet by the Federal Ministry for Economic Affairs and Energy with almost 1,1 Millionen Euro.

In mining, the compressed air driven underground hammers are widespread due to the high drilling progress that can be achieved with them. However, since water can run into the borehole at a greater depth, these fail quickly and are then unsuitable. Deep drilling is generally associated with very high costs, which is why the hammer drilling method in hard rock would bring significant advantages. The aim of the OBH project is therefore the development of a mud-driven hammer drill, which will make deep geothermal drilling in hard rock more economical. Percussive drilling methods are significantly more effective here than conventional cutting or scratching methods. With the knowledge, projects for the generation of geothermal energy, i.e. green energy, can be implemented sooner. Since most hammers have so far worked with air, it should also be proven that the concept of a rotary hammer driven by drilling fluid is just as effective and realistic.

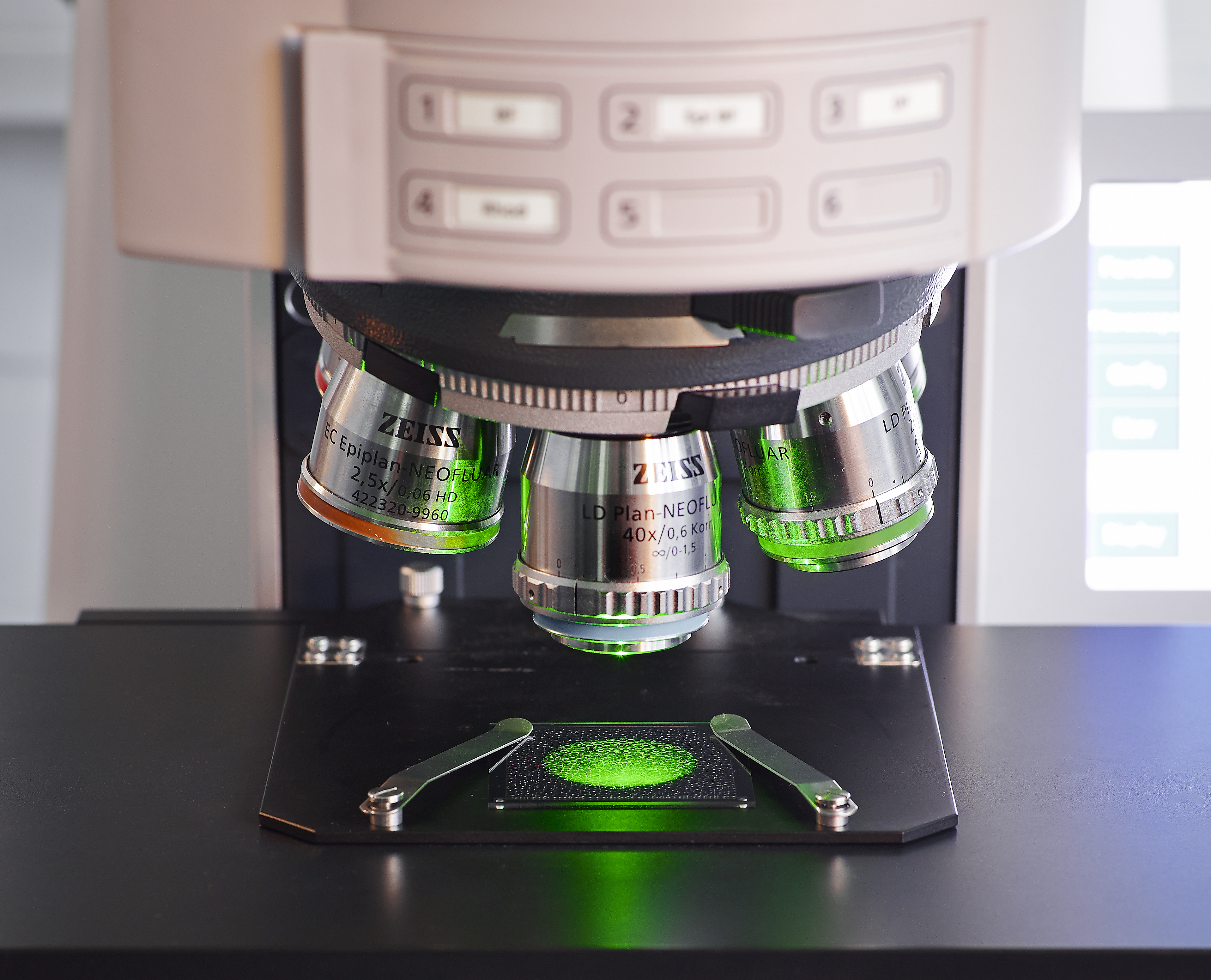

The energy to operate the hammer drill is obtained directly from the kinetic energy of the drilling fluid. The first experiments by the ITE researchers took place on the Drilling Simulator Celle (DSC) in the hardware simulator. There, a prototype was first used to drill horizontally into a rock chamber. Afterwards, three weeks of experiments with the developed drilling tool took place in the 30 meter deep test shaft at ITE. With the help of these tests, it has so far been possible to demonstrate above all that the rotary hammer achieves a high drilling rate in hard rock, can be operated with conventional drilling fluid and can be used in the drill string in a way that is compatible with MWD systems.

Contact:

TU Clausthal

Nadine Kaiser

Telefon: +49 5323 72-3952

E-Mail: nadine.kaiser@tu-clausthal.de