Glycol Foaming Behavior in TEG-Water-Natural-Gas Systems at Elevated Pressures

(Text nur in Englisch verfügbar)

Introduction

Glycol foaming is one of the major operational problems in glycol dehydration units. Foaming reduces the contact between the glycol and natural gas, and this reduces the drying of the processed gas. Thus, off-specification gas may result. Glycol-water mixtures may foam when entrained hydrocarbons mix with the glycol. Also impurities such as suspended solids, salts and even corrosion inhibitors and excessive turbulence can cause glycol to foam. Sometimes antifoams/defoamers are added to stop glycol from foaming but this measure is just temporal and excessive use of the antifoams promote glycol foaming. The knowledge of glycol foaming behavior in TEG-water-natural gas system at elevated pressures is necessary to optimize glycol usage, achieve minimal glycol loss and also maintain the required dew point temperature of the dry gas. Most glycol dehydration units are designed to treat 1 million standard cubic feet (MMSCF) of natural gas using about 0.12 gallon of glycol. If glycol usage exceeds this limit then there is need to arrest the situation to avert further loss of glycol.

Scope

Based on the above introduction, the proposed thesis should include the following:

- Overview of glycol dehydration process

- Understand the causes and challenges of glycol foaming in glycol dehydration unit

- Emphasize industry best practices to prevent glycol foaming

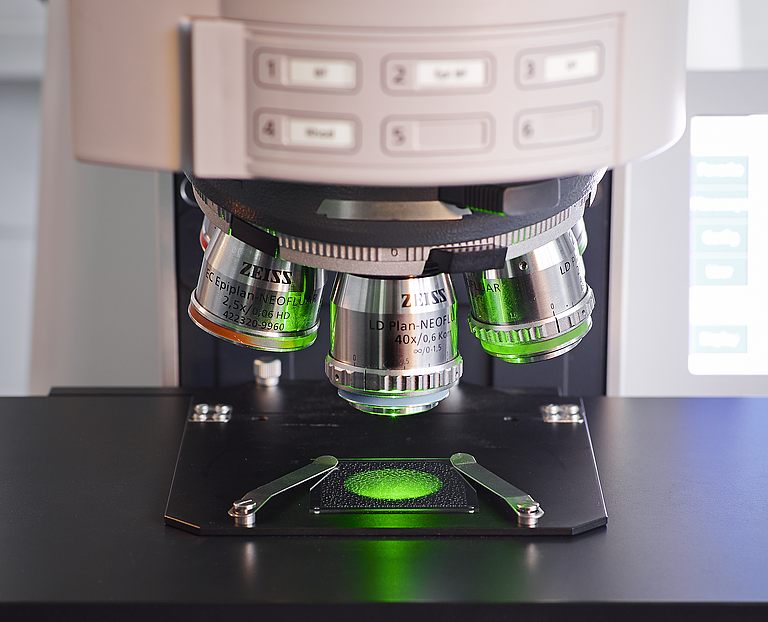

- Perform laboratory experiment on glycol foaming behavior in TEG-water-natural gas system

- Quantify glycol loss in TEG-water and in TEG-water-natural gas systems at process conditions

- Analyze the experimental results and highlight key information as it concerns glycol dehydration process

Literatur

- Haque E., Xu Q., Palanki S. (2019). Glycol loss minimization for natural gas dehydration plant under upset conditions. Industrial & engineering chemistry research, 58 (5). doi.org/10.1021/acs.iecr.8b04675.

- Ibeh S.U., Chibueze S.E., Obah B., (2017). “An Investigation of Dehydration Inefficiencies and Associated Design Challenges in a Gas Dehydration Unit-A Case Study of X-Gas Plant”. Journal of Advances in Petroleum Exploration and Development, ISSN 1925-5438, Vol 14, No1 pp 47-54.

- Maini B.B., and Ma V. (1986). Laboratory evaluation of foaming agents for high temperature applications –I. Measurements of foam stability at elevated temperatures and pressures. Journal of Canadian Petroleum Technology. Pg. 65-69.